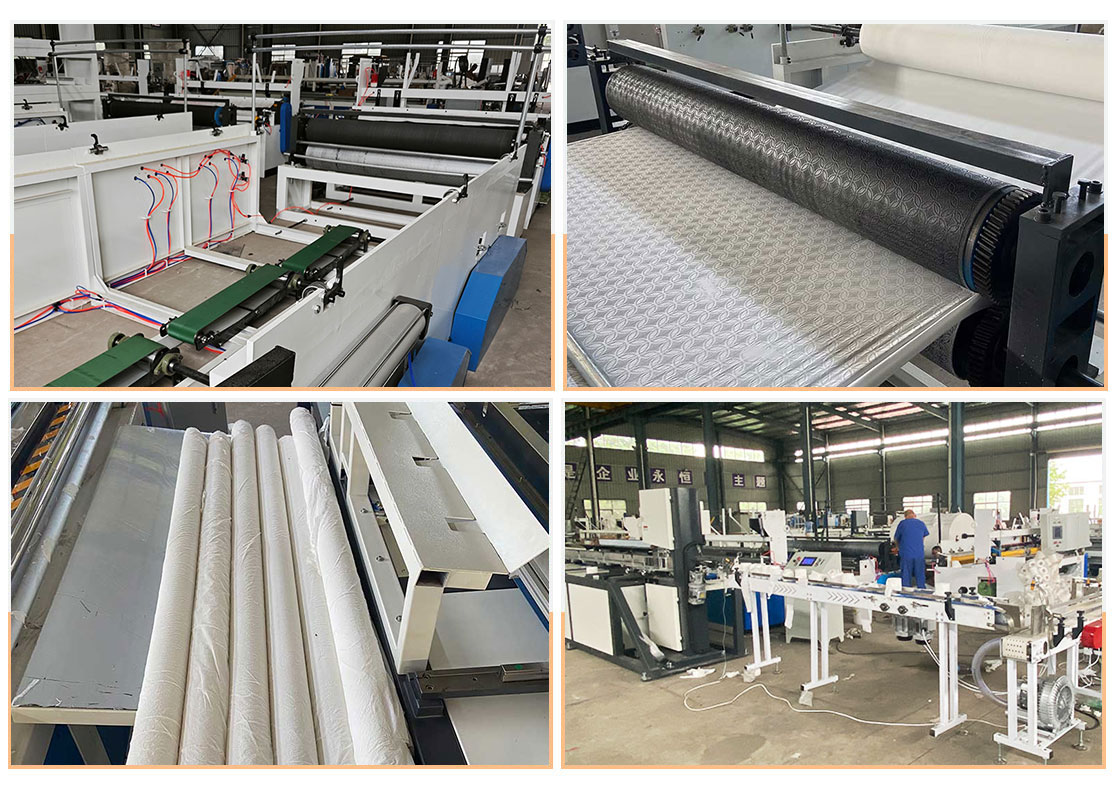

Product Introduction

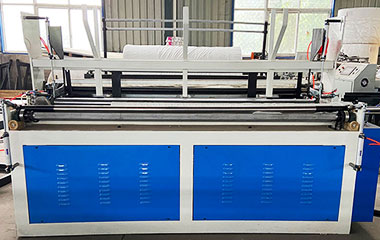

Automatic toilet paper rewinding machine is used for producing toilet paper roll and kitchen tower,Raw material from jumbo roll after full embossing or edge embossing, then perforation, end cutting and spray the tail glue become a log. Then it can working with cutting machine and packing machine to become the finished products. The machine is controlled by PLC, people operate it through touch screen, the whole process is automatic, easy to operate, lower the man cost. And Our machine can special-made according to clients' requirements.

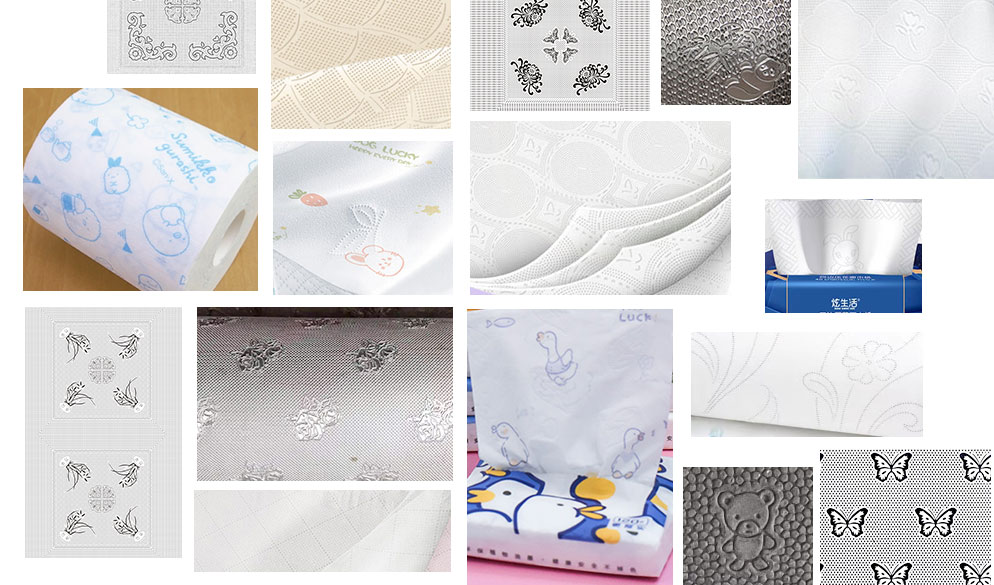

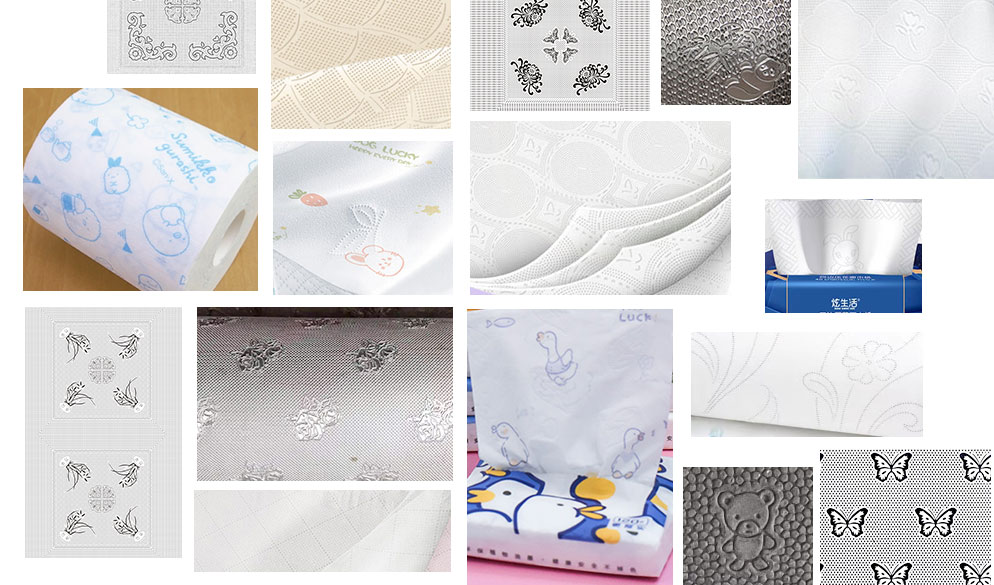

Toilet Paper Display

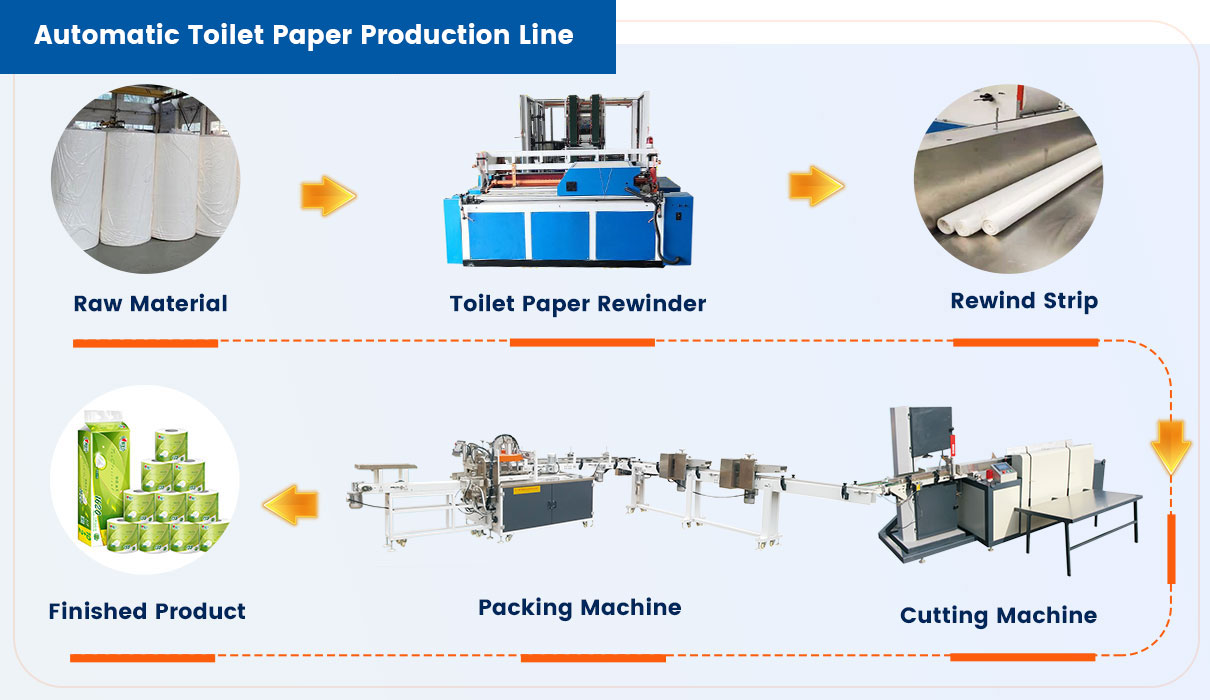

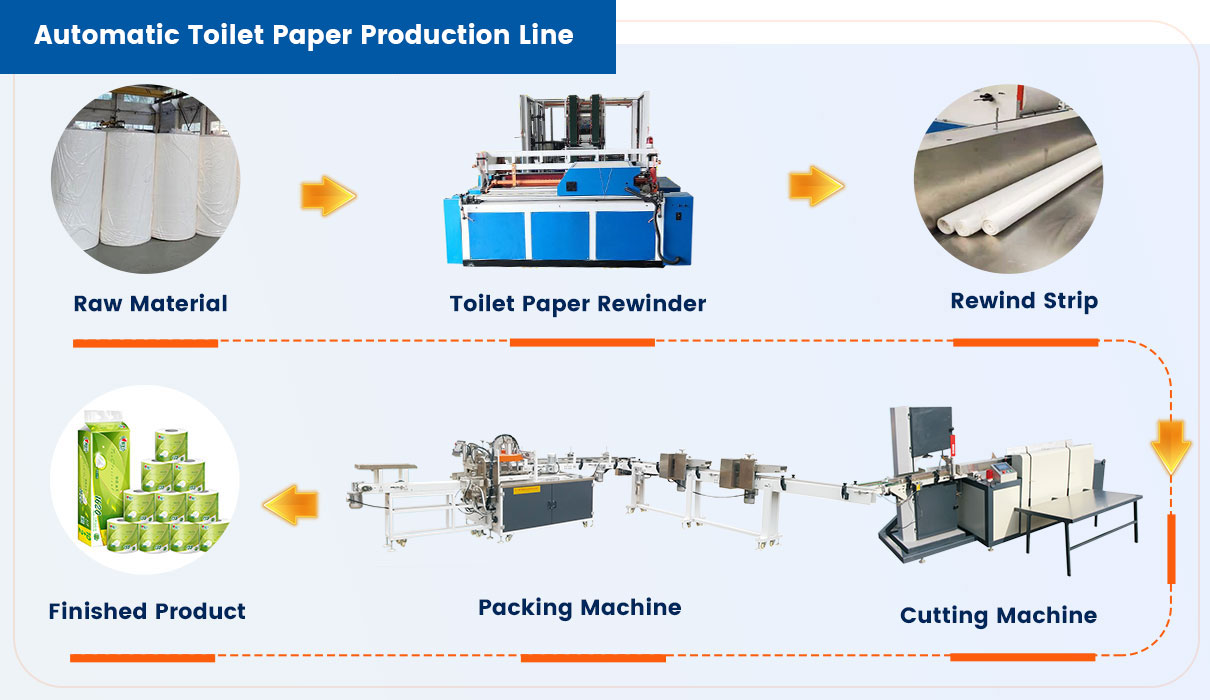

Two Production Solutions

YG toilet roll making machine manufacturer provides customers with a one-stop shopping experience. YG supplies all the equipment needed to produce toilet paper. From raw materials to finished paper rolls, the equipment that needs to be used includes a toilet paper rewinding machine, a toilet tissue cutter machine (log saw cutter, rotary cutter), and a toilet paper packing machine (single roll, one bag). For each piece of equipment, YG provides There are many different models to meet the needs of toilet paper manufacturers with different specifications.

Product Features

1Using PLC computer to program the finished paper in the rewinding process to achieve the tightness and looseness of the different tightness to solve the looseness of the finished product due to long-term storage.

2Full-automatic rewinding machine can choose double-sided embossing, gluing compound, which can make paper more soft than single-sided embossing, the effect of double-sided finished products is consistent, and each layer of paper does not spread when used, especially suitable for processing.

3The machine is equipped with processing unintentional, solid, paper tube toilet paper, which can instantly switch between products, and can also be selected according to user needs.

4Automatic trimming, glue spraying, sealing, and shafting are completed synchronously, so that there is no paper loss when the roll paper is cut into the band saw and packaged, which greatly improves the production efficiency and the grade of the finished product. Easy to enable.

5Pneumatic belt feeding, double reel and each axis of the original paper have independent tension adjustment mechanism.

Embossing Pattern Selection

In order for you to quickly find the pattern you like, some are listed below for you to choose from, In addition, you can consult us for exclusive pattern designs.

You May Need

Related Products

Related Products

Good Feedback

Good Feedback