Product Introduction

Waste Tire Recycling Production Line of Producing Rubber Granule Rubber Dust can crush waste tires or rubber products into rubber granules and powder to realize the recycling and reusing of waste rubbers. As a professional manufacturer, we can provide you the best solution based on your different raw materials.

Raw Materials

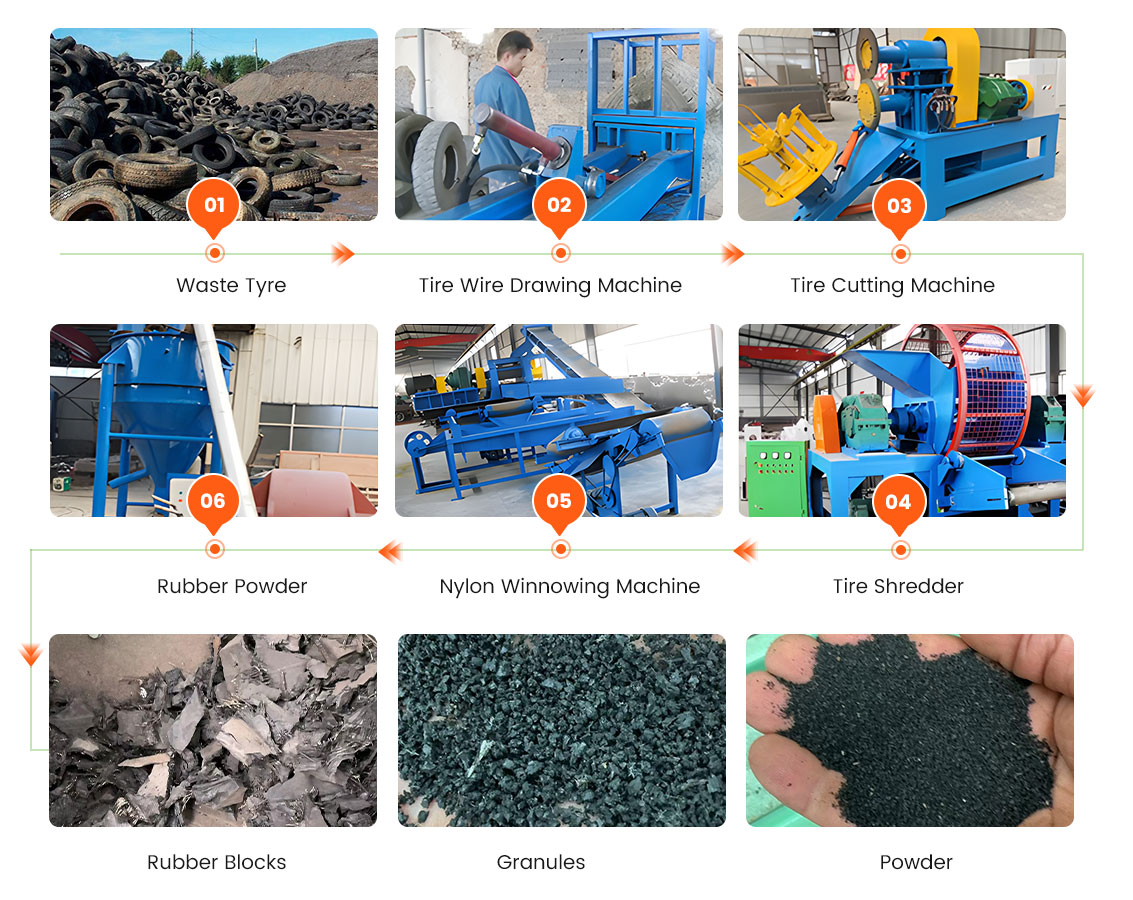

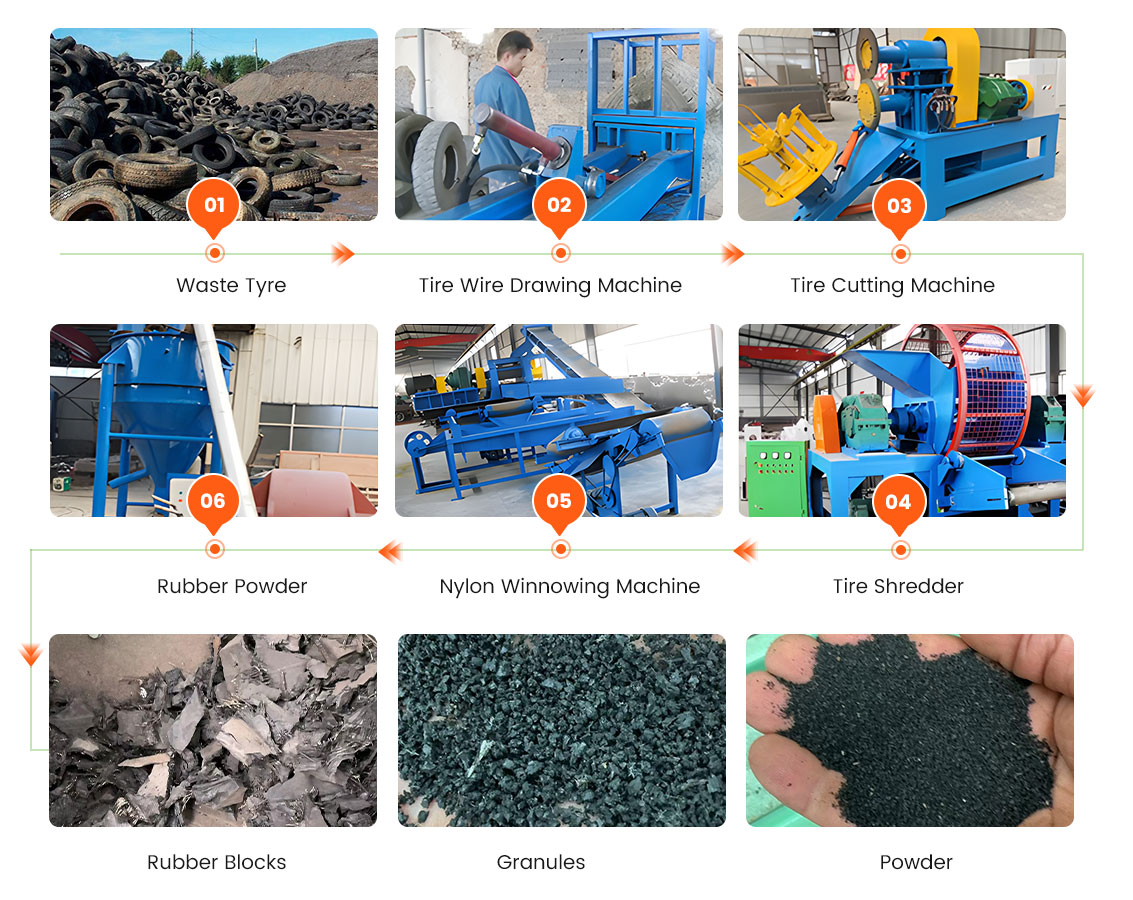

Process flow

Main Equipment Display

1Tire rim cutting machine

used to cut off the steel rim of the tire, separate the tire from the steel rim, and prepare for subsequent processing steps.

2Tire strip cutting machine

Cut the tire after removing the steel rim into strips for further crushing.

3Tire block cutter

cuts strip tires into blocks to reduce the volume of tires and facilitate subsequent processing.

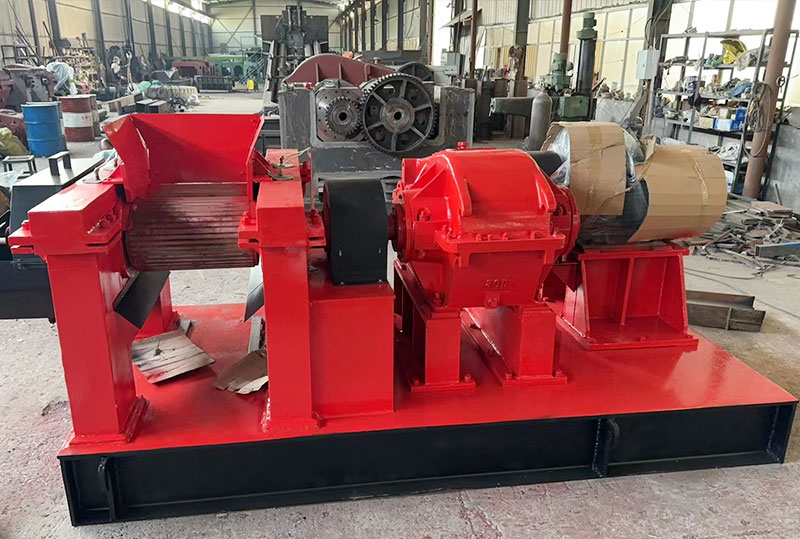

4Crusher

powerfully crushes tire blocks and crushes them into smaller particles.

5Magnetic separator

uses magnetism to separate metal substances such as steel wire from tire particles to achieve separation of rubber and metal.

6Rubber medium crusher

further crushes rubber particles to meet specific particle size requirements.

Application Areas

Good Feedback

Good Feedback

Related Products

Related Products