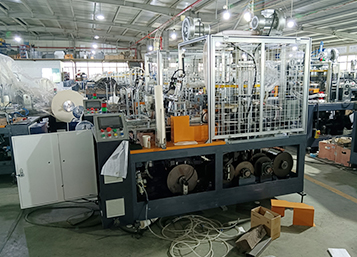

High-Speed Automated Production With Precise Dimensional Control

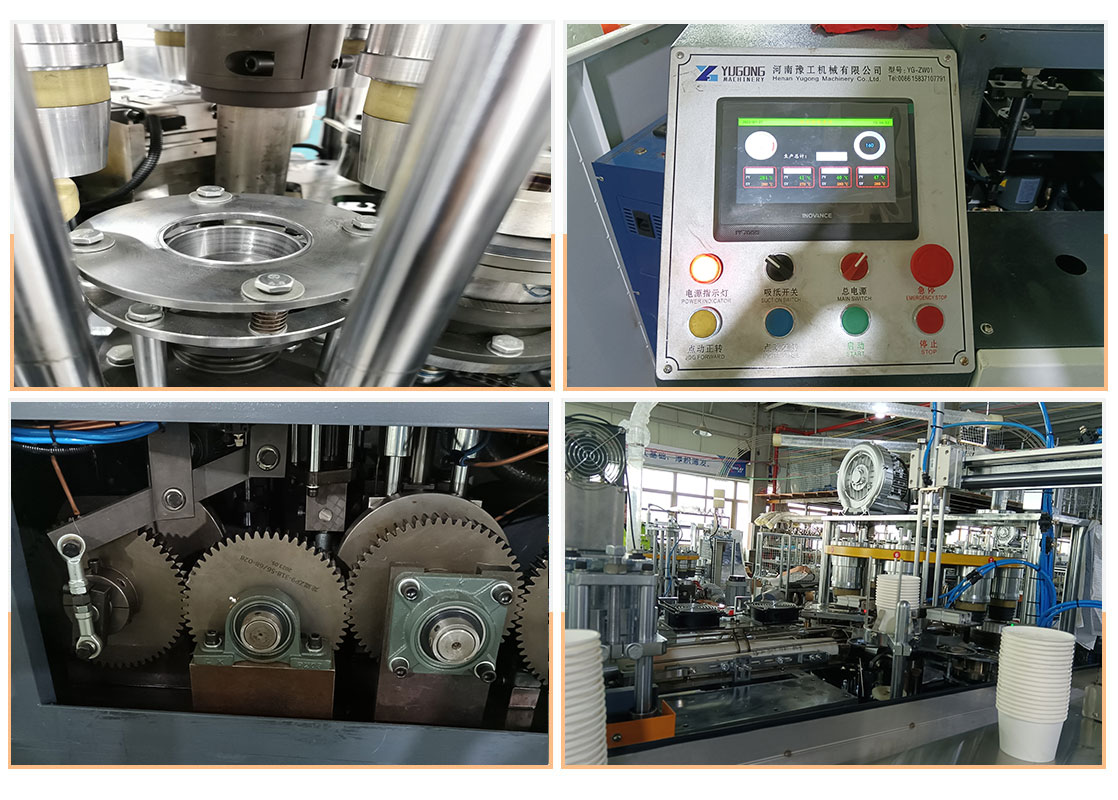

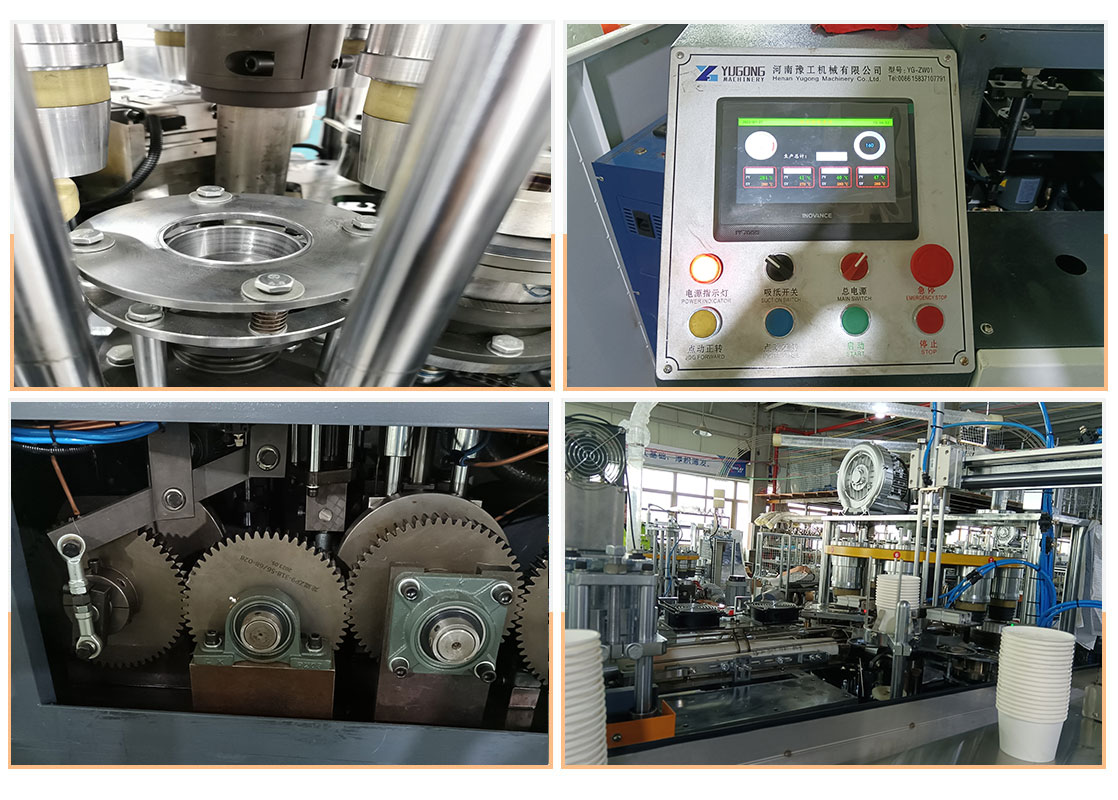

Through precise mold design and mechanical control, YG paper cup machine can ensure that the produced paper cups have high dimensional accuracy. The indicators such as cup height, diameter, and cup mouth flatness can strictly meet the standard requirements, ensuring the appearance quality and performance of the paper cups.

During the paper cup forming process, the paper cup machine can evenly heat and pressurize the paper, making the cup wall smooth and wrinkle-free, the bottom of the cup and the cup body firmly combined, and it is not easy to leak and other problems, which improves the quality stability and durability of the paper cup.

Customized Service & Meeting Customers' Diverse Needs

Whether you need to produce disposable paper cups of regular sizes or customize paper cups of special specifications, our paper cup machine can easily handle it. It has a flexible mold replacement system that can quickly change molds according to your needs to produce paper cups of different capacities, shapes and patterns to meet the diverse needs of multiple industries such as catering, coffee, milk tea, and baking.

Paper Cup Machine Parameters

|

Model

|

YG-800

|

YG-C800

|

YG-S800

|

|

Paper Cup Size

|

2-9OZ

|

2-16OZ

|

2-16OZ

|

|

Raw Material

|

One-side or two-side PE coated paper

|

|

|

Speed

|

80-100 pcs/min

|

70-90 pcs/min

|

100-120 pcs/min

|

|

Suitable paper weight

|

160-350g;±20g

|

160-350g;±20g

|

160-350g;±20g

|

|

Voltage supply

|

380V, 50HZ

|

380V, 50HZ

|

380V, 50HZ

|

|

General power

|

7.8 kw

|

5.5 kw

|

7kw

|

|

Working Air Source

|

NO

|

NO

|

0.6-0.8mpa; 0.4m³/min

|

|

Net weight

|

1680kg

|

1680kg

|

2000kg

|

|

Measurement

(L*W*H)

|

2115*1000*1700mm

|

2115*1000*1700mm

|

Main engine

|

2180*1050*1600mm

|

|

Cup holder

|

900*600*1800mm

|

|

Cup Side Sealing

|

Copper bar heating

|

Evergreen Ultrasonic

|

Evergreen Ultrasonic

|

|

Bottom Knurling

|

Heating

|

Heating

|

Hot Air System

|

|

We can customize machine and mold according to customer’s requirement.

|

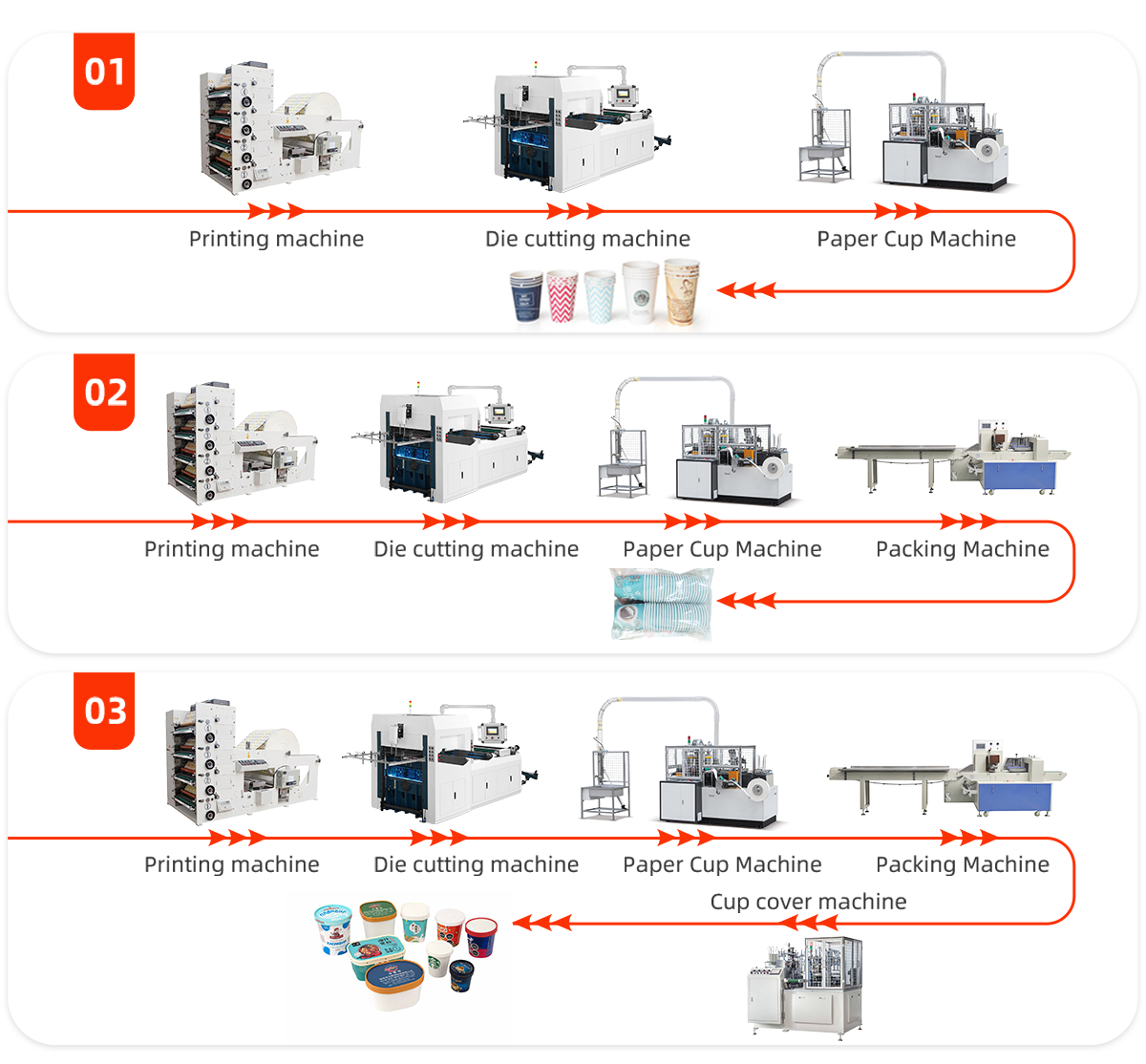

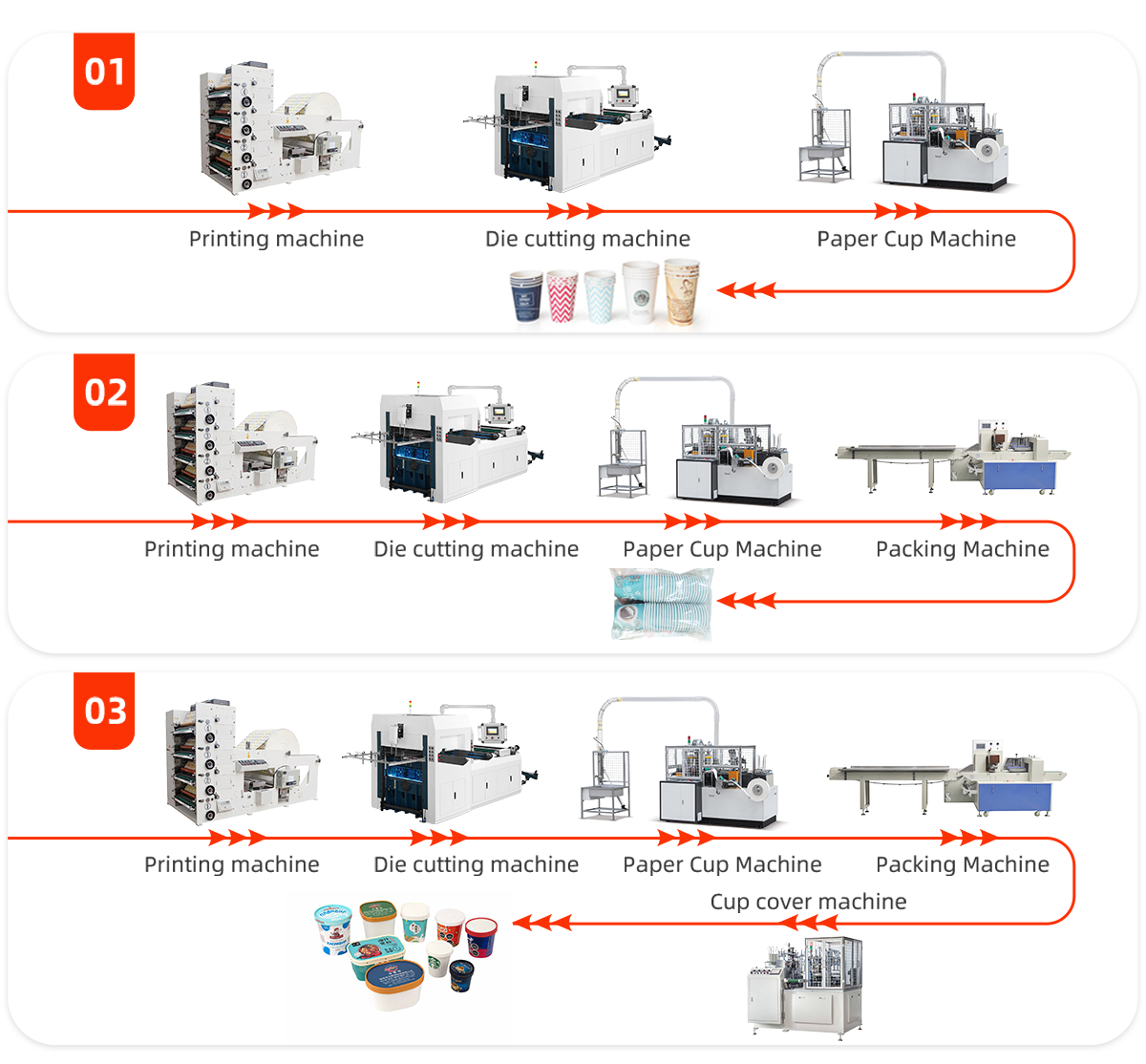

Paper Cup Making Process

In Yugong, you can complete one-stop purchasing with peace of mind, from raw materials to printing to die-cutting to paper cup molding. According to your different needs, appropriate equipment models are configured with high efficiency and stable operation, helping you to achieve low investment and high profits!

Yugong Paper Cup Machine Highlights

1The paper cup machine can run continuously for a long time without frequent shutdown for manual intervention. Through the coordinated work of the automated paper feeding system, paper cup forming system, bottom sealing system, hemming system and other links, a continuous production process from paper to paper cup is realized.

2The overall structure adopts modular design, and the connections between various components are tight, easy to disassemble and assemble, which facilitates the maintenance and care of the equipment. At the same time, the key components of the equipment are made of high-quality materials and advanced manufacturing processes, with high wear resistance and reliability, reducing the probability of failure.

3By replacing molds of different specifications and adjusting equipment parameters, the paper cup machine can produce paper cups of various sizes and capacities, such as common 9-ounce and 12-ounce paper cups, as well as paper cups of special specifications, meeting the needs of different customers.

4With touch screen or button control, operators can easily master the operation methods of the equipment after simple training, and can start, stop, adjust parameters and other operations of the equipment.

You May Need

-

Die Cutting Machine

Free Quote

-

Flexo Printing Machine

Free Quote

Good Feedback

Good Feedback

Related Products

Related Products